Riccardo Lucchi founded the company "Lucchi R. Elettromeccanica srl", orientated towards production and repairs of DC electric motors, repulsion/induction motors for sandblasters and equipment for test benches

Within the first ten years of activity, a small production of lathes and battery chargers for electric cars is started. In the late '60s, the company specializes in the construction of electromechanical auction equipment that was used at the auction of the fish, fruit and flower market.

During the '70s, the experience gained in variable speed electric motors' field has led Lucchi R. Elettromeccanica to specialize in forklift motors' production, becoming the official supplier of leading companies such as Carer and Cesab.

Giorgio Lucchi graduated in electrical engineering with a thesis on linear motors and brought innovation to the company thanks to the relationship with the university environment. Giorgio Lucchi, in fact, thanks to the support and freedom of action granted him by his father, immediately began to make radical changes: he computerized the various company departments, designed and autonomously built prototypes of automatic machines for electrical windings' production. This drive for innovation led the company to conquest new and important market areas, in Italy and abroad.

With the early passing away of his father, Giorgio Lucchi assumed the operational control of the company. Making investments to optimize the production of DC motors for traction application (mainly required by the material handling market) and 6 to 40 kW motors (with voltage below 120 V and "H" insulation class) he became one of the largest Italian manufacturers in the sector.

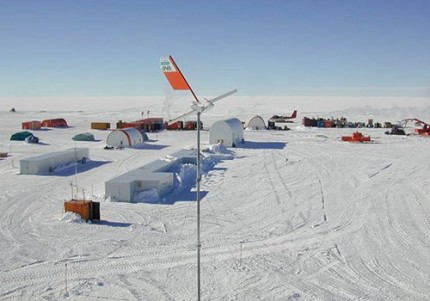

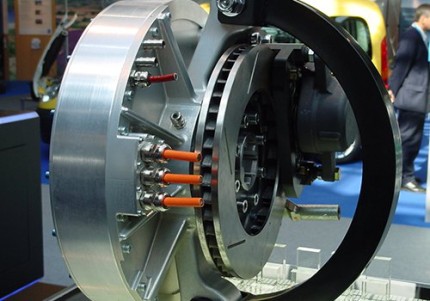

Lucchi R. Elettromeccanica, in collaboration with the Universities of Rome "La Sapienza" and "Roma Tre", combines its production with research on alternative energy and electric motors for automotive application. Through this partnership, the company developed the first motor for public transport with a new geometry called "axial flux" that allows the inclusion of the motor inside the wheel without using gear ratios due to its high torque density. At the same time, under CNR - National Research Council's request, the company developed an axial flux generator for wind application, intended for permanent operation in extreme environments at low temperatures.

Lucchi R. Elettromeccanica started collaborating with the Finmeccanica group (today Leonardo), and in particular with Ansaldo Ricerche, for the construction of electric motors for various applications in the propulsion sector. The outstanding results achieved in the first activities undertaken led the company to new requests from the group, creating a partnership still active today.

Lucchi R. is currently involved in numerous application fields: from marine to ground propulsion for special applications, from servo-drives for the automatic control of agricultural vehicles to the industrial field of operating vehicles, up to the field of power generation. The company, which has maintained strong relationships over the years with both the university and suppliers, makes it possible to meet the needs of customers in terms of design, industrialization and production of rotating electrical machines quickly and with a wide range of power and torque available. To be continued...